PVC Marble Sheet Installation

PVC Marble Sheet Installation, usually there are three simple installation methods widely enjoyed by install workers for PVC marble sheet: Method A, direct on wall installation; Method B, aluminium alloy decor clips installation; Method C, sealant installation. There are also some videos for PVC marble sheet installation reference.

Actually, there can be many methods for this PVC marble sheet installation. Buyers or builders can check them on Youtube by search " PVC marble panel installation", it would show short videos on this subject. Buyers or builders can choose the most favor and practical installation method for them.

Actually, there can be many methods for this PVC marble sheet installation. Buyers or builders can check them on Youtube by search " PVC marble panel installation", it would show short videos on this subject. Buyers or builders can choose the most favor and practical installation method for them.

Tools Required For Installations

Here are some tools needed for this installation. With these tools, the installation work would be very easy and quick. Builders may do not require all of them, just choose the necessaries for your exact installation method.

Tape ruler, machine saw, free nail adhesive, adhesive gun, steel nail gun, steel nails, double sided adhesive tape, cutter knife, angle grinder, 45 degree machine cutter, electric screw driver, self tape screws.

We can offer installation tools for our buyers along with the goods if buyer can not get these tools in local overseas.

Tape ruler, machine saw, free nail adhesive, adhesive gun, steel nail gun, steel nails, double sided adhesive tape, cutter knife, angle grinder, 45 degree machine cutter, electric screw driver, self tape screws.

We can offer installation tools for our buyers along with the goods if buyer can not get these tools in local overseas.

PVC Marble Sheet General Installation Method

PVC Marble Sheet Installation Method A: Direct on wall installation

Step 1: Requiring.

Usually, requiring a flat wall surface is necessary before installing the panel on wall. The PVC marble sheet can be installed on the wall surface directly if the wall surface is flat and clean. Cement mortar wall is also okay. If there is small raised area, flatten it. If there is small concave area, use foam sealing agent to make it flat.

Step 2: Draw Line and install decor clips.

Using tape ruler and marker draw out the horizontal and vertical lines for expected installation areas. And install aluminium alloy decor clips onto proper positions.

Step 3: Cutting.

Using machine saw cut the whole sheet into small pieces with expected size. Tidy and neat the edges using sandpaper. Make the back clean for pointing liquid nail adhesive purpose.

Step 4: Pointing Adhesive.

Pointing the liquid nail adhesive on the back of small pieces.

Step 5: Sticking and Peeling

Stick the small piece on the expected position on the wall softly and firmly. Sticking for minutes to make sure the piece and the wall stick well. Peel off the protective film on the surface of installed piece.

Usually, requiring a flat wall surface is necessary before installing the panel on wall. The PVC marble sheet can be installed on the wall surface directly if the wall surface is flat and clean. Cement mortar wall is also okay. If there is small raised area, flatten it. If there is small concave area, use foam sealing agent to make it flat.

Step 2: Draw Line and install decor clips.

Using tape ruler and marker draw out the horizontal and vertical lines for expected installation areas. And install aluminium alloy decor clips onto proper positions.

Step 3: Cutting.

Using machine saw cut the whole sheet into small pieces with expected size. Tidy and neat the edges using sandpaper. Make the back clean for pointing liquid nail adhesive purpose.

Step 4: Pointing Adhesive.

Pointing the liquid nail adhesive on the back of small pieces.

Step 5: Sticking and Peeling

Stick the small piece on the expected position on the wall softly and firmly. Sticking for minutes to make sure the piece and the wall stick well. Peel off the protective film on the surface of installed piece.

PVC Marble Sheet Installation Method B: Aluminium alloy decor clips installation

For this method of installation, please well noted that the thickness of the sheet should be proper for the holding of the decorative line. If not, please install with liquid nail adhesive method.

Step 1: Requiring.

To require a flat surface before installing the PVC marble sheet like installing other same decorative UV boards, on the wall surface installation worker can install a 3 mm thick wood sheet with air nail using air nail gun. Clean its surface.

Step 2: Nailing.

On the wood sheet, near the wall foot install the foot line, in the wall corner install the decor clips internal angle bead, and then install the "H" shape decorative line on proper position according to the expected size the PVC marble sheet would be cut into.

Step 3: Cutting.

Cut the PVC marble sheet into pieces with expected sizes using saw machine, and make the edges tidy and neat using sandpaper.

Step 4: Inserting and Peeling.

Insert the PVC marble sheet pieces into the decor clips, hammer it softly, and peel off the protective film on surface.

Step 1: Requiring.

To require a flat surface before installing the PVC marble sheet like installing other same decorative UV boards, on the wall surface installation worker can install a 3 mm thick wood sheet with air nail using air nail gun. Clean its surface.

Step 2: Nailing.

On the wood sheet, near the wall foot install the foot line, in the wall corner install the decor clips internal angle bead, and then install the "H" shape decorative line on proper position according to the expected size the PVC marble sheet would be cut into.

Step 3: Cutting.

Cut the PVC marble sheet into pieces with expected sizes using saw machine, and make the edges tidy and neat using sandpaper.

Step 4: Inserting and Peeling.

Insert the PVC marble sheet pieces into the decor clips, hammer it softly, and peel off the protective film on surface.

PVC Marble Sheet Method C: Adhesive Installation

Step 1: Requiring.

To require a flat surface before installing the PVC marble sheet like installing other same decorative UV boards, on the wall surface installation worker can install a 3 mm thick wood sheet with air nail using air nailer. Clean its surface.

Step 2: Cutting and Trimming.

Cut the PVC marble sheet into pieces with expected sizes using saw machine, use the trimming maching to trim the edge into 45 degree angle, then make the edges tidy and neat using sandpaper. Given exact situation, up and down edges or 3 of 4 edges need this trimming process.

For the edge trimming 45 degree angle issue, also named V groove or V joint, if the panel piece is thick enough, then the appearance of this trimming contributes to good looking greatly, if the panel piece is too thin, not thick enough for this trimming, then this trimming can be discarded, and use matching colored aluminium alloy decorative lines to decorate the area of bordering is also great.

Step 3: Pointing.

Clean the back of every piece, point the liquid nail adhesive on the cleaned back of every piece.

Step 4: Sticking.

Stick the pointed adhesive piece on the expected position of the wood sheet, and push them together softly and firmly properly for minutes to make sure they stick well.

Step 5: Filling Seam.

Put the filing seam material sealant into the 45 degree angle position of two bordering pieces.

Step 6: Cleaning and Peeling.

Cleaning the surface of installed PVC marble sheet, and the surplus filling seam material. Peel off the protective film on surface softly.

To require a flat surface before installing the PVC marble sheet like installing other same decorative UV boards, on the wall surface installation worker can install a 3 mm thick wood sheet with air nail using air nailer. Clean its surface.

Step 2: Cutting and Trimming.

Cut the PVC marble sheet into pieces with expected sizes using saw machine, use the trimming maching to trim the edge into 45 degree angle, then make the edges tidy and neat using sandpaper. Given exact situation, up and down edges or 3 of 4 edges need this trimming process.

For the edge trimming 45 degree angle issue, also named V groove or V joint, if the panel piece is thick enough, then the appearance of this trimming contributes to good looking greatly, if the panel piece is too thin, not thick enough for this trimming, then this trimming can be discarded, and use matching colored aluminium alloy decorative lines to decorate the area of bordering is also great.

Step 3: Pointing.

Clean the back of every piece, point the liquid nail adhesive on the cleaned back of every piece.

Step 4: Sticking.

Stick the pointed adhesive piece on the expected position of the wood sheet, and push them together softly and firmly properly for minutes to make sure they stick well.

Step 5: Filling Seam.

Put the filing seam material sealant into the 45 degree angle position of two bordering pieces.

Step 6: Cleaning and Peeling.

Cleaning the surface of installed PVC marble sheet, and the surplus filling seam material. Peel off the protective film on surface softly.

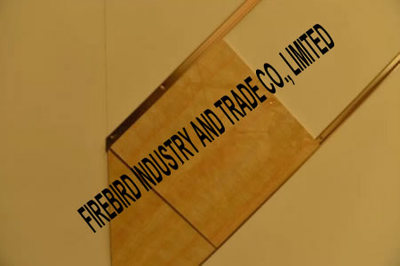

PVC Marble Sheet Background wall decoration

Here is a case for background wall decoration using PVC marble sheet.

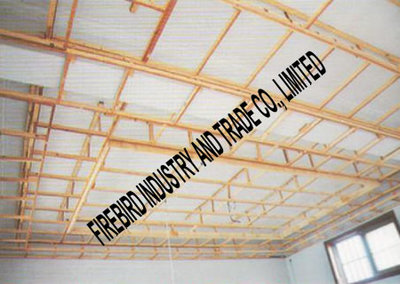

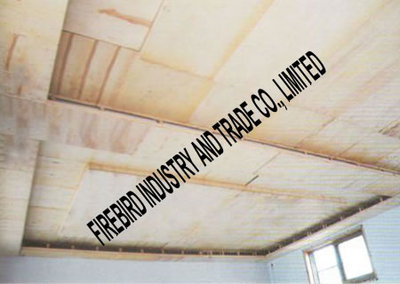

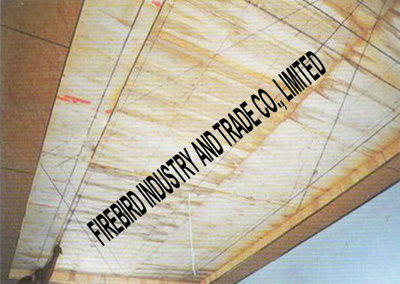

PVC Marble Sheet Ceiling Decoration

PVC marble sheet installation tips:

1. Liquid nail adhesive is very proper for this kind of PVC marble sheet or panel installation than other adhesives or glues.

Regarding the free nail adhesive we offer, we work with good adhesive factory for this sheet cladding purpose, it can help prevent our buyers or end consumers from ending up dent surface or cave-in surface for their wrong choice on improper adhesive. This way, it can bring good reputation to our buyers or distributors and enjoyable product experience to our end consumers.

2. If your wall is painted, the paint on wall surface should be peeled off, or installing a wood sheet, to meet the requirement before the panel pieces installation.

3. Among these 3 methods mentioned above, the Method A is most widely adopted.

4. For the edge trimming 45 degree angle issue, if the panel piece is thick enough, then the appearance of this trimming contributes to good looking greatly, if the panel piece is thin, not thick enough for this trimming, then this trimming can be discarded, and use matching colored aluminium alloy decorative lines to decorate the area of bordering is also great.

5. Regarding the filling material sealant, you can consult your installing workers or local shops from which you buy the PVC marble sheet or PVC wall panel.

6. This PVC marble sheet, like other boards or panels for wall cladding decoration, it can be installed with or without aluminium alloy decorative lines by favor of consumers.

7. Holding Force. The main holding force between the wall and PVC marble sheet is adhesive. Proper adhesive can offer good holding force, serve long time and show excellent performance. So we recommend proper free nail adhesive for installation of this PVC marble sheet.

8. An experienced installation worker can work smartly and neatly according to your exact installation situation.

9. The best way to know how to install the sheets is consulting with experienced installation workers in your location. Or just outsourcing the installation work to those experienced installation workers.

10. If builders have any problems regarding installation, just contact us.

11. For installation tools, if necessary, we also can buy and ship them with goods for our buyers, like machine saw, machine cutter, air compressor, nail gun, nails, glue, and so on.

Regarding the free nail adhesive we offer, we work with good adhesive factory for this sheet cladding purpose, it can help prevent our buyers or end consumers from ending up dent surface or cave-in surface for their wrong choice on improper adhesive. This way, it can bring good reputation to our buyers or distributors and enjoyable product experience to our end consumers.

2. If your wall is painted, the paint on wall surface should be peeled off, or installing a wood sheet, to meet the requirement before the panel pieces installation.

3. Among these 3 methods mentioned above, the Method A is most widely adopted.

4. For the edge trimming 45 degree angle issue, if the panel piece is thick enough, then the appearance of this trimming contributes to good looking greatly, if the panel piece is thin, not thick enough for this trimming, then this trimming can be discarded, and use matching colored aluminium alloy decorative lines to decorate the area of bordering is also great.

5. Regarding the filling material sealant, you can consult your installing workers or local shops from which you buy the PVC marble sheet or PVC wall panel.

6. This PVC marble sheet, like other boards or panels for wall cladding decoration, it can be installed with or without aluminium alloy decorative lines by favor of consumers.

7. Holding Force. The main holding force between the wall and PVC marble sheet is adhesive. Proper adhesive can offer good holding force, serve long time and show excellent performance. So we recommend proper free nail adhesive for installation of this PVC marble sheet.

8. An experienced installation worker can work smartly and neatly according to your exact installation situation.

9. The best way to know how to install the sheets is consulting with experienced installation workers in your location. Or just outsourcing the installation work to those experienced installation workers.

10. If builders have any problems regarding installation, just contact us.

11. For installation tools, if necessary, we also can buy and ship them with goods for our buyers, like machine saw, machine cutter, air compressor, nail gun, nails, glue, and so on.

Some Installation Sites

PVC marble sheet installation videos

|

|

|

The simplest installation method is to install the whole sheet in size 1220 x 2440 mm on wall directly with glue. The wall on which the sheet would be installed should be clean, no accessories needed, no other tools needed. This way comes to a decent marble finish wall surface. Save big cost for business owners in commercial places.

PVC Marble Sheet can also be installed without any other decorative marble profiles and decor lines. But client can use colored materials to decorate the seams.

PVC Marble Sheet for interior wall renovation.

All rights reserved for text, photos and videos.