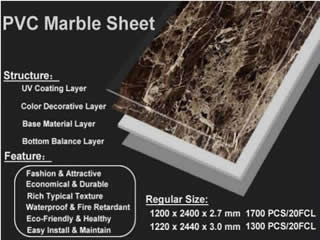

PVC Marble Sheet Feature

PVC Marble Sheet Introduction

|

PVC marble sheet is mainly made from PVC resin and calcium carbonate powder, consequently also call stone plastic composite marble panel, shorted as SPC marble panel. PVC marble panel is also often used name.

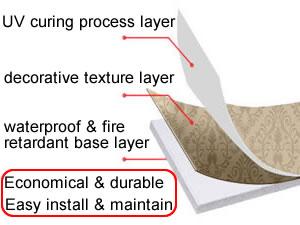

Besides the surface protective film layer, there are 3 layers in this sheet to form outstanding features: Top layer: UV curing process durable layer. Middle layer: texture color decorative layer. Bottom layer: waterproof and fire retardant base layer. Also named basement and balance layer. |

PVC Marble Sheet Feature

|

UV curing process

flame retardant, moisture proof anti-acid, alkali, corrosion, scratch fashionable diverse grain color eco-friendly, no fading 100% asbestos free formaldehyde free, no radiation heat & acoustic insulation light & hard, simple shipping & stock economical & durable easy install & maintain |

PVC Marble Sheet Case

|

PVC marble sheets are enjoyed widely in interior wall decoration for commercial and residential places, like hotel, hospital, office building, corridor, meeting room, office room, club, theater, restaurant, cafe house, department store, fashion store, lab, clubs, boutique, chambers, restaurant, cafe, inn, villa, salon, house, museum, exhibition store, and so on.

|

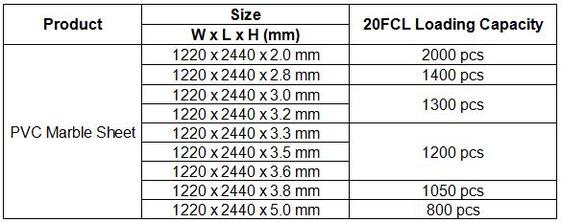

PVC Marble Sheet Size

The issue among thickness, strength and price

For this PVC marble panel, the thicker, the more strength, the higher price; the thinner, the less strength, the lower price. Too thick, it tends to be more excessively heavy but not necessary. Among these thickness sizes we often produce, 3.2 mm is middle, this thickness level can possess very satisfied strength for cutting, sawing and wall paneling. Also this 3.2 mm thickness enjoys economical price level. This is a nice balance for importers, distributors and end consumers.

To meet competitive price satisfaction of our dealers and end consumers, nowadays we produce 3.0 mm and 2.7 mm most often, these two thickness are popularly accepted, also it can show good product performance and outstanding features.

To meet competitive price satisfaction of our dealers and end consumers, nowadays we produce 3.0 mm and 2.7 mm most often, these two thickness are popularly accepted, also it can show good product performance and outstanding features.